Andon Systems and AR: Transforming Manufacturing

Introduction:

To revolutionize your industries the digital transformation as embraced the software system in manufacturing industries with integration of Augmented Reality(AR) based Andon systems which has flourished the intercommunication within the tools and machines through enhancing productivity and reducing the downtime and leverage the analytics with automated escalation and delegation to maintain qualitative production system.

ANDON SYSTEM IN MANUFACTURING:

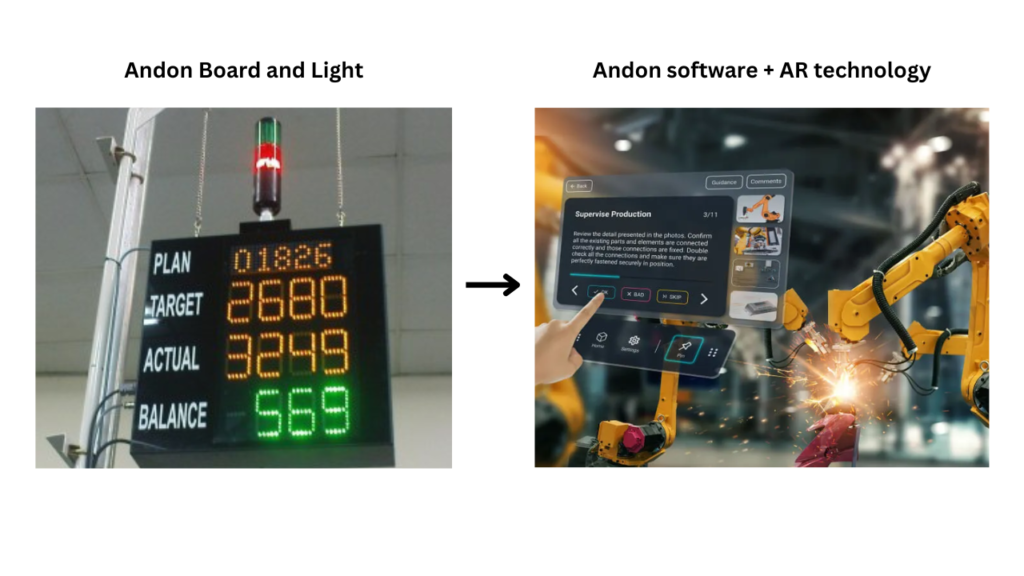

Andon systems display on the production monitoring board about the production activity and identifies the action required problem area. It facilitates communication between the workers and senior department with digital signage on the production floor and Andon lights.

The Andon system indicates the production targets and displays production achieved in the real time; it enables production count and enhances the efficiency then also tracks the machine status.

Andon Systems and AR in Manufacturing Industry:

AR powered Andon systems provides cutting edge augmented reality solutions to manage and maintain the production line with revolutionized technology to reduce downtime with continuous increased production and efficiency.

The integration of AR in the Andon system evolves the transition in the workforce with a proactive, responsive and streamline functioning level in the production floor.

- It reduces downtime to increase productivity and efficiency

- It displays the product name been in production process

- It enables product count

- It analyze the machine status

- It identifies the problematic area in production house and provide real time alerts and monitoring to the concerned personnel

The future benefits of AR integration in Andon system:

- Digital twin: The digital twin empowers with the connection of physical shop floor and digital dynamic work environment which facilitates increased production and enables the workers to accomplish the targets by reducing overlapping work.

- Instant Visibility: The connection of digital twins provides real time insights with alerts and notification of multiple production units at one place to improve effectiveness among the workers. It synergy between virtual realms and tangible machines.

- Quick troubleshooter: The automated alert and monitoring system enables the worker to perform corrective work through the study of display board and machine status are analyzed about the condition working or not working if any failure of working machine advance alerts will be provided to the concerned person for immediate intervention the problem will be solved quickly saves money and time

CONCLUSION

AR transformed the automated Andon system in manufacturing industry to improve the effectiveness of workers and efficient working of machinery by enabling tracking the production activity of targets that should do to achieve this transition mainly focus on improvising the production by reducing downtime which enhances the manufacturing concern with smart factories with digital solution.