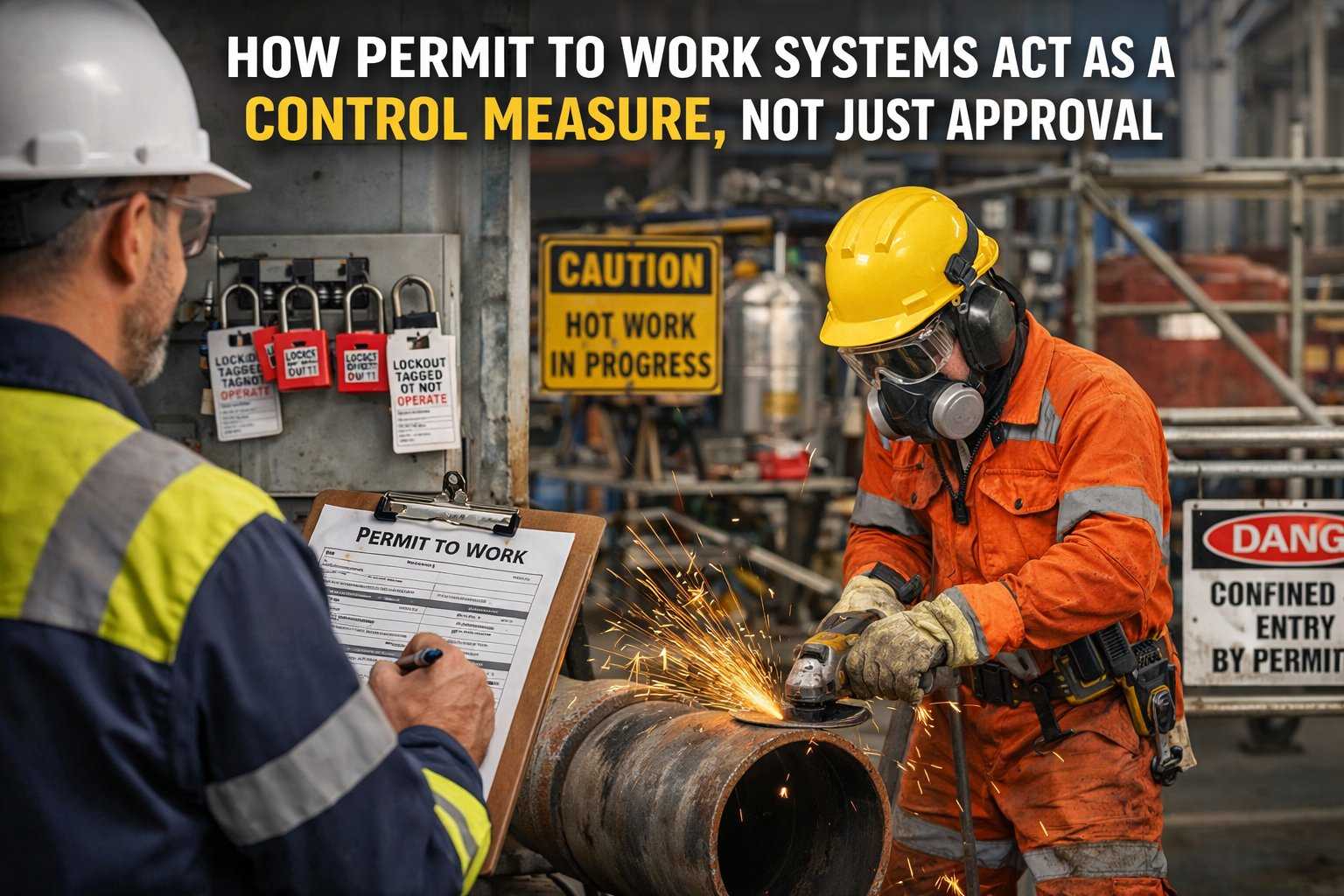

How Permit to Work Acts as a Control Measure, Not Just Approval

In many high-risk industries, a Permit to Work (PTW) system is often misunderstood as a simple authorization form—a document signed before starting hazardous work. In reality, a well-designed Permit to Work system functions as a powerful control measure that prevents incidents, protects workers, and ensures regulatory compliance. When implemented correctly, it becomes an active risk management tool rather than a passive approval process.

Understanding the True Purpose of a Permit to Work

A Permit to Work is a formal, documented procedure used to control high-risk activities such as hot work, confined space entry, electrical maintenance, working at height, and line breaking. The purpose is not merely to grant permission but to ensure that all hazards are identified, assessed, and controlled before work begins.

Industries such as oil and gas, manufacturing, construction, mining, and utilities rely on structured PTW systems to manage operational risks. Organizations like the Occupational Safety and Health Administration emphasize the importance of hazard control and structured work authorization procedures in reducing workplace incidents.

The key difference lies in mindset: approval focuses on authorization, while control focuses on prevention.

Permit to Work as a Risk Control Framework

A robust Permit to Work system acts as a layered control framework. It integrates several safety elements into one structured process:

1. Hazard Identification and Risk Assessment

Before a permit is issued, the work scope is reviewed, and potential hazards are identified. This step ensures that risks such as fire, toxic exposure, energy release, or structural instability are evaluated. Control measures are then defined to eliminate or minimize these risks.

This proactive approach transforms the permit into a preventive mechanism rather than a reactive document.

2. Isolation and Energy Control

For tasks involving machinery, pipelines, or electrical systems, proper isolation is critical. A Permit to Work system verifies that lockout/tagout procedures, depressurization, or de-energization steps are completed before work starts.

Without structured verification, isolation errors can lead to catastrophic incidents. The permit ensures accountability and confirmation of safe conditions.

3. Defined Roles and Responsibilities

A PTW system clearly defines who is responsible for issuing, approving, executing, and monitoring the work. This eliminates ambiguity and prevents miscommunication between departments such as operations, maintenance, and safety teams.

When roles are clearly assigned, safety becomes a shared responsibility rather than an individual assumption.

4. Communication and Coordination

High-risk activities often occur simultaneously in industrial environments. A Permit to Work system prevents conflicting operations, such as welding near flammable materials or maintenance work during active production.

By ensuring cross-functional communication, the permit acts as a coordination control, reducing the likelihood of simultaneous operation risks.

5. Verification Before, During, and After Work

Unlike a simple approval form, a PTW system includes multiple checkpoints:

- Pre-work verification

- Monitoring during execution

- Post-work inspection and closure

This lifecycle approach ensures continuous control rather than one-time authorization.

Moving from Paper-Based Approval to Digital Control

Traditional paper-based permits often suffer from delays, incomplete documentation, and limited visibility. In contrast, digital Permit to Work systems integrate risk assessments, isolation certificates, checklists, and real-time approvals into a centralized platform.

Modern safety solutions such as those offered by Soft Designers enhance PTW effectiveness by:

- Automating approval workflows

- Linking permits with risk assessments and Job Safety Analysis (JSA)

- Providing real-time status tracking

- Ensuring audit-ready documentation

- Integrating with incident and inspection management systems

This digital transformation strengthens the permit’s role as an active control mechanism.

Compliance and Legal Protection

Regulatory bodies expect organizations to demonstrate systematic hazard control. A properly implemented Permit to Work system provides documented evidence that risks were identified and mitigated before work began.

In the event of an audit or investigation, a comprehensive PTW record shows that due diligence was exercised. This protects both employees and management by demonstrating structured compliance.

Preventing Major Incidents

History has shown that many industrial accidents occur due to failures in communication, isolation, or risk assessment — not simply because permission was granted. When Permit to Work (PTW) is treated as a control measure, it helps prevent serious incidents by strengthening operational discipline and accountability.

- Unauthorized work

- Conflicting simultaneous operations

- Inadequate isolation

- Incomplete hazard assessment

- Lack of supervisory oversight

By embedding safety into the workflow, the permit becomes a preventive barrier against major incidents.

Creating a Safety-First Culture

A Permit to Work system also reinforces organizational culture. When employees see that hazardous tasks require structured evaluation and documented controls, they recognize that safety is prioritized over speed.

This cultural shift encourages workers to:

- Report unsafe conditions

- Follow defined procedures

- Participate in risk assessments

- Take ownership of workplace safety

The permit becomes more than a document—it becomes a symbol of disciplined safety management.

From Approval to Active Risk Management

Treating Permit to Work as a mere approval step reduces it to paperwork. Treating it as a control measure transforms it into a strategic risk management tool.

An effective PTW system:

- Identifies hazards before exposure

- Controls energy sources

- Ensures coordination

- Documents accountability

- Supports regulatory compliance

- Strengthens safety culture

Organizations that adopt this approach significantly reduce workplace incidents and operational disruptions.

Conclusion

A Permit to Work system is not just about granting permission. It is a structured control process designed to prevent accidents, manage hazards, and ensure safe execution of high-risk tasks. When supported by digital tools and integrated safety management systems, it becomes a powerful safeguard that protects people, assets, and reputation.

For industries operating in complex and high-risk environments, shifting the perception of PTW from approval to control is not optional—it is essential for sustainable safety performance and operational excellence.