Why Incident Tracking Software Is Essential for Workplace Safety:

Introduction

Workplace safety is very important for every organization. Even when safety rules are followed, incidents like injuries, near misses, unsafe actions, or damage to property can still happen. If these incidents are not recorded and reviewed properly, the same problems may happen again, which can lead to serious accidents and legal issues.

Incident Tracking Software helps organizations record, track, and analyze all safety incidents in one digital system. Instead of using paper registers, companies can easily monitor incidents, identify risks, and take quick corrective actions. This improves safety performance, reduces repeat incidents, and helps organizations maintain safety compliance.

Benefits of Incident Tracking Software:

Incident Tracking Software helps organizations handle workplace incidents in an organized and efficient way. It gives one main place to record incidents, near misses, and unsafe conditions, so nothing is missed or forgotten. The software allows quick reporting, easy investigation of the root cause, and automatic follow-up actions. By identifying problems early and taking corrective steps, it helps prevent the same incidents from happening again and improves overall workplace safety.

Incident Tracking Software also saves time and reduces paperwork by replacing manual registers and spreadsheets. Employees can report incidents quickly using a computer or mobile device, even from the worksite. Safety teams can track the status of each incident, assign corrective actions, and ensure they are completed on time. This improves communication, increases accountability, and helps organizations stay compliant with safety regulations while creating a safer work environment for everyone.

1. Quick and Accurate Incident Reporting

Employees can report incidents immediately using digital forms, reducing paperwork and ensuring accurate information is captured.

2. Better Visibility and Control

All incidents are stored in one central system, making it easy to track status, identify trends, and monitor recurring safety issues.

3. Faster Corrective Actions

Safety managers can assign actions, set deadlines, and track closures to prevent similar incidents from happening again.

4. Improved Compliance

The software maintains proper records and audit trails, helping organizations meet regulatory and safety compliance requirements.

5. Stronger Safety Culture

Encouraging easy reporting of incidents and near misses helps employees feel responsible for safety and promotes continuous improvement.

Role of Incident Tracking Software in Workplace Safety

Incident Tracking Software helps organizations keep the workplace safe and follow safety rules easily. It allows companies to record and manage all workplace incidents in one place instead of using paper files or emails. This makes it easier to understand what went wrong and take quick action.

By tracking incidents, near-misses, and corrective actions, the software helps identify risks early and prevent future accidents. It also encourages employees to report safety issues without fear, helping to build a positive and strong safety culture across the organization.

Key Roles of Incident Tracking Software

- Centralized Incident Reporting

All incidents, near-misses, and hazards are reported and stored in one system. - Faster Response & Corrective Action

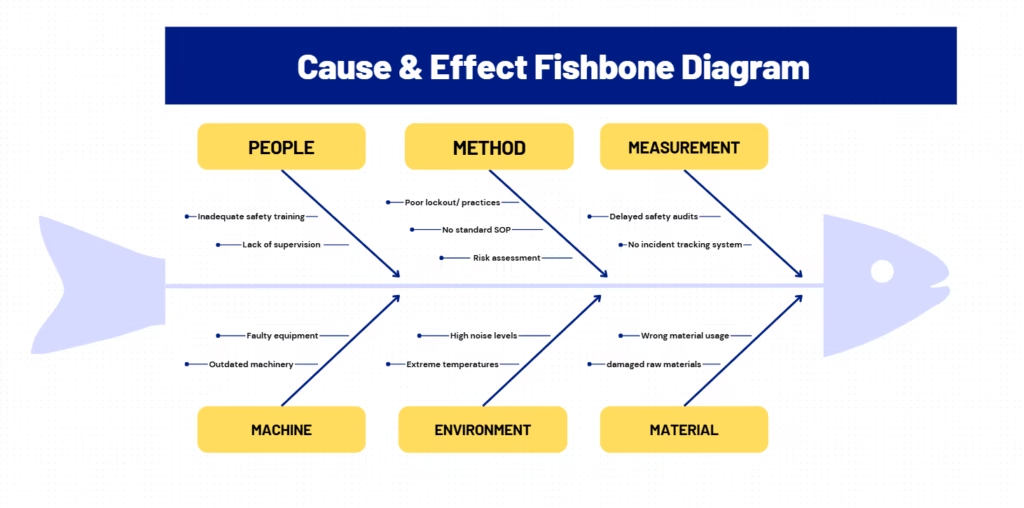

Helps safety teams take immediate action to reduce risks and avoid repeat incidents. - Root Cause Analysis

Identifies the real reasons behind incidents to prevent future occurrences. - Improved Compliance

Supports compliance with safety regulations and safety audit requirements. - Data-Driven Safety Decisions

Provides reports and insights to improve safety policies and procedures. - Enhanced Employee Participation

Encourages employees to report safety issues easily using digital or mobile tools.

Incident Tracking Software – Use Case & Tool

| Use Case | Tool / Feature Used | Outcome |

|---|---|---|

| Injury Reporting | Digital Incident Reporting Forms | Quick and accurate recording of injuries with complete details |

| Near-Miss Reporting | Near-Miss Capture Tool | Identifies potential risks before they become serious accidents |

| Unsafe Acts & Conditions | Hazard Reporting Tool | Early detection and removal of workplace hazards |

| Incident Investigation | Incident Investigation Module | Identifies root causes and prevents repeat incidents |

| Corrective & Preventive Actions | CAPA Management Tool | Ensures timely closure of safety actions |

| Compliance Management | Audit Trails & Compliance Reports | Meets legal and regulatory safety requirements |

| Safety Trend Analysis | Analytics & Dashboard Tool | Helps management make data-driven safety decisions |

Choosing the Right Safety Incident Tracking Software:

Softdesigners offers a reliable approach when it comes to choosing the right safety incident tracking software for your workplace. Selecting the right tool is essential because it helps organizations report, monitor, and resolve incidents efficiently, ensuring a safer environment for employees. The software should be user-friendly, provide real-time updates, and allow easy analysis of incidents to prevent future occurrences. By focusing on features like customizable reports, automated alerts, and mobile accessibility, companies can make safety management simpler and more effective.

When choosing incident tracking software, it is important to see whether it suits your company’s needs. The software should work smoothly with your existing systems, help you understand incident trends clearly, and support safety rules and compliance. The right incident tracking software helps improve workplace safety, saves time, reduces risks, and increases productivity by making sure every incident is recorded, tracked, and resolved properly.

Conclusion

Incident Tracking Software is no longer optional it is a critical tool for maintaining a safe and compliant workplace. By providing a structured way to report, investigate, and analyze incidents, the software helps organizations reduce workplace risks and prevent accidents before they occur. It improves response time, ensures regulatory compliance, and promotes a proactive safety culture where employees feel responsible for safety.