“The Future of Traceability in Manufacturing: How Software is Changing the Game”

Traceability in manufacturing is becoming increasingly important as global supply chains become more complex. Traceability is the ability to track the origin, location, and movement of materials, components, and products throughout the entire lifecycle of a product. It enables manufacturers to trace the source of their materials, ensure product quality, and meet compliance requirements. In the future, traceability in manufacturing will become even more important as global markets become more competitive and regulatory requirements become stricter. Manufacturers will need to be able to track and trace materials and products from their source to their destination. To do this, they will need to develop and use advanced technologies, such as blockchain, Internet of Things (IoT) sensors, and cloud computing. These technologies will allow manufacturers to capture and store data throughout the entire product lifecycle. This data can be used to verify product quality, trace the source of materials, and ensure compliance with regulations. Additionally, these technologies will enable manufacturers to quickly detect and respond to problems, such as product recalls or counterfeiting. In the future, traceability will also be used to improve supply chain visibility and efficiency.

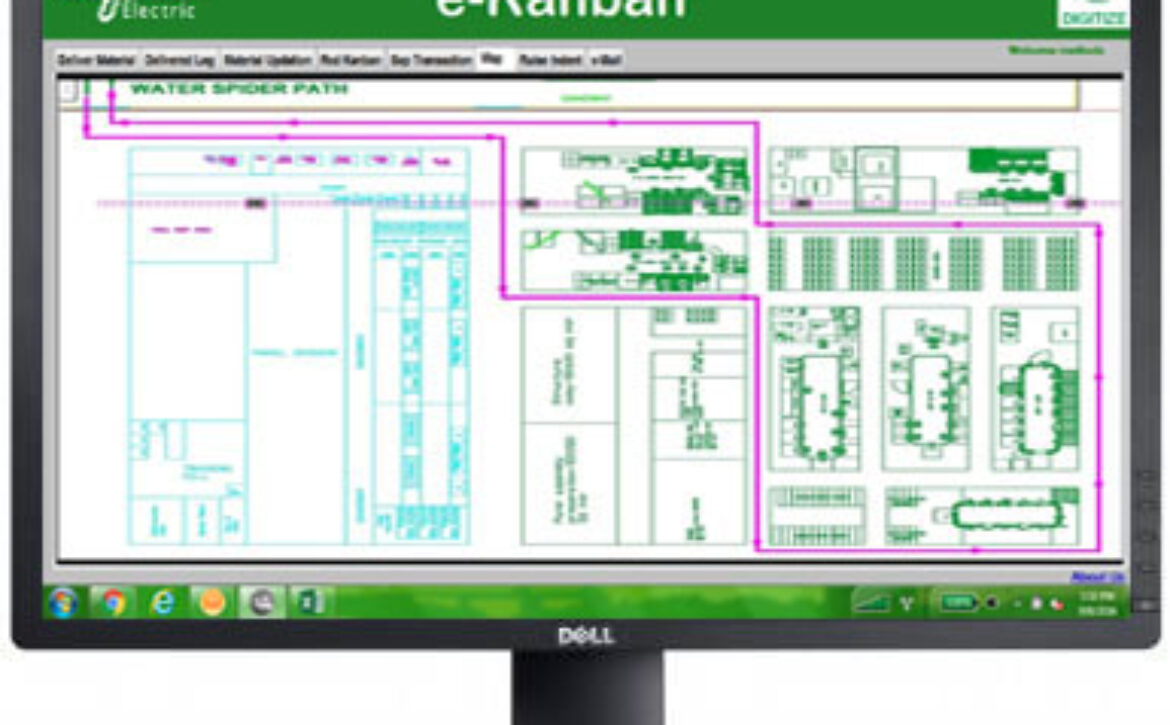

Traceability software is revolutionizing the way businesses track and monitor their products. The software allows companies to track their products from the raw material all the way to the end customer, providing those businesses with an unprecedented level of visibility and control. This ensures that their products are meeting the highest standards and are free from any contamination or defects. The software also helps businesses to ensure that their products are compliant with all applicable regulations, which can help to protect their company from costly fines and litigation. Traceability software also helps to streamline the supply chain, reducing costs and improving efficiency. Finally, the software helps to improve customer satisfaction by providing customers with detailed information about their products, including where they come from and how they were made.

Benefits of Traceability system for production:

The use of traceability software is changing the way manufacturers track and trace products and materials. By providing real-time visibility into the production process, traceability software is helping manufacturers improve product quality, reduce production costs, and maintain regulatory compliance. Traceability software can also be used to track materials from the start of the supply chain all the way to the finished product. This ability to track materials from the point of origin to the point of use helps manufacturers reduce supply chain costs and ensure product safety and quality. Traceability software can also track production processes, allowing manufacturers to optimize their processes and reduce waste. In addition, traceability software can be used to monitor and manage inventory levels in real-time, allowing manufacturers to respond quickly to changing demand. This helps manufacturers reduce lead times, improve customer service, and increase profitability.

Finally, traceability software can help manufacturers meet regulatory compliance requirements. By tracking and tracing products and materials, manufacturers can ensure that they are meeting all applicable safety and environmental regulations. As traceability software continues to evolve, it is clear that it will play an increasingly important role in helping manufacturers improve their operations and reduce costs.

Want to know more about the TRACEABILITY SOFTWARE

Establish a comprehensive traceability system to track raw materials, production processes and finished products