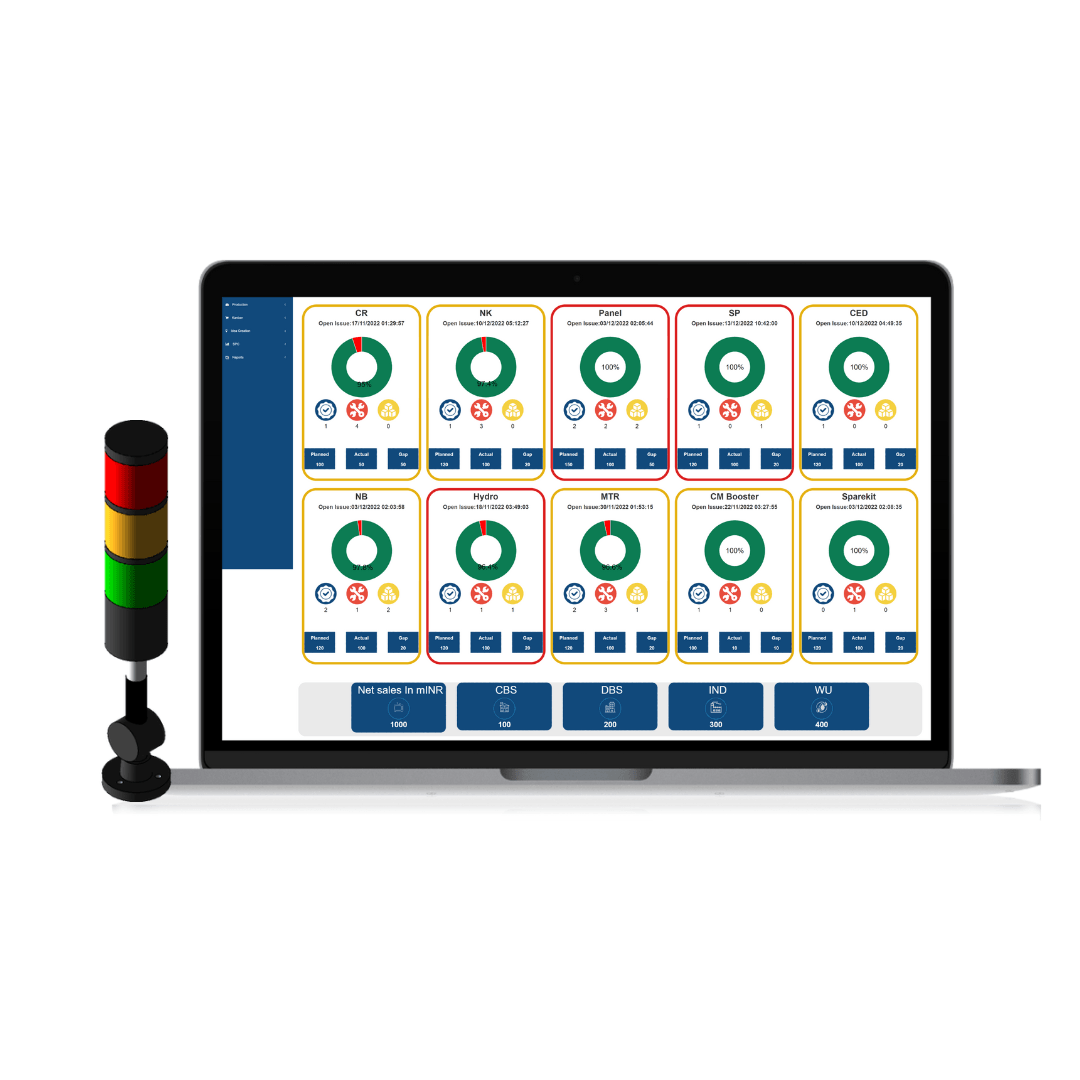

How Andon line or system is useful?

Andon system enables employees to notify key decision-makers about manufacturing problems so that effective corrective action can be taken. It improves the flow of information in case of problems and also improves product quality and better continuous opportunities. The real-time machine status that you will get:

MTTR (Mean Time To Repair)

An MTTR is a maintenance metric that measures the average time required to troubleshoot and repair failed equipment.

MTBF (Mean Time Between Failures)

Measuring MTBF is one way to learn more about a failure and minimize its effects. An MTBF review aids the maintenance team in reducing downtime, saving money, and operating more efficiently.

Summary Reports

Real-time reporting keeps you informed of what’s been produced, what has not been produced, and the overall efficiency of your machines.

Live Machine Status

It allows you to connect every machine to see and understand how your entire shop floor is performing.

Downtime details

Andon is the easiest way to prevent unplanned downtime.