E- Preventive maintenance :

Preventive maintenance is employed to prevent the equipment from falling while the machine is still working so that it is possible to reduce breakdowns in machines.

Working :

The system we use here is time-based, consists of maintenance software that helps emergency repairs.

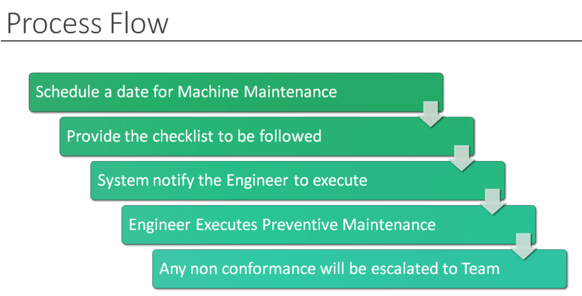

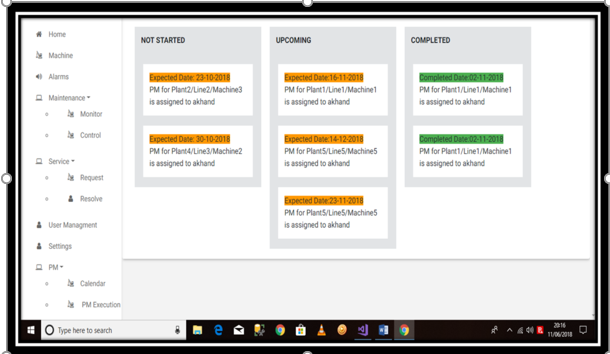

Companies make a schedule or plan for machine maintenance. Preventive maintenance planning includes cost-based, time-based and failure-based planning. Potential failure is identified and an intervention time will be scheduled or planned for preventive action to take place before the functional failure happens. Calender-based maintenance allows you to schedule a recurring work order until a specified time interval is reached. Preventive maintenance is scheduled at recurring intervals. A checklist is maintained for orders to be executed.

The schedule is needed to compute the history of failures and to detect the useful life of the component.

The e-preventive maintenance schedule may include things such as cleaning, lubrication, oil changes, adjustments, repairs, inspecting and replacing parts, and partial or complete overhauls that are regularly scheduled. This software performs all the maintenance operations by itself. This stores a company’s maintenance data in a cloud to easily keep track of all inspections, repairs, and replacements. With all data conveniently stored in one place, preventive maintenance software can be used to effectively manage work orders, purchase orders, inventory and maintenance records.

Maintenance in industries consists of activities like routine maintenance, maintenance testing, and diagnostic testing.

Routine maintenance activities can be scheduled on a time-based manner which will be governed by e-maintenance. Maintenance testing activities include using test equipment, which is predictable and can be foreseen by using e-maintenance. Some other activities like repair cannot be scheduled prior which cannot be used under e-maintenance.

It is possible to find the frequency of failure since machine status will be monitored accurately and data can be obtained.

Machines will be repaired or replaced based on predetermined intervals in e-preventive maintenance and will be updated automatically.

Equipment status is found by immediate detection of failure hence, equipment failure will be prevented making the equipment shut down and then it is restored. Also, the probability of failure can be detected.

Advantages :

- E-preventive maintenance will reduce lost production, costs.

- This prevents downtime and expensive repair costs.

- This will prevent equipment failure before it happens.

- This increases safety and reduces any injury risks.

- The maintenance approach is proactive in nature and time based (periodic).

Applications across industries :

- Manufacturing industries.

- FMCG

- Pharmaceutical industries.

- Chemical industries.

References :

1.http://eprints.utem.edu.my/17525/1/E-Preventive%20Maintenance%20Warning%20System%2024%20Pages.pdf

3. file:///C:/Users/SoftDesigners/Downloads/Published.pdf

4. https://www.lce.com/pdfs/The-PMPdM-Program-124.pdf

Related links :

Andon System | Leading Manufacturer in India

FAQ :

1. Will this reduce the total maintenance costs of the machine?

Of course, it will reduce maintenance costs and downtime.

2. What will be the estimated cost?

This costs lower than the corrective as well as predictive maintenance.