Why Choose Our AI-Driven Inspection Tracking System

Seamless Production Monitoring

Keep track of every stage in your production line, ensuring flawless output and consistent product quality.

Predictive Equipment Maintenance

Identify potential machinery issues before they occur, reducing downtime and extending equipment life.

Smart Defect Detection

Leverage AI to spot defects in real time, improving accuracy and reducing human error.

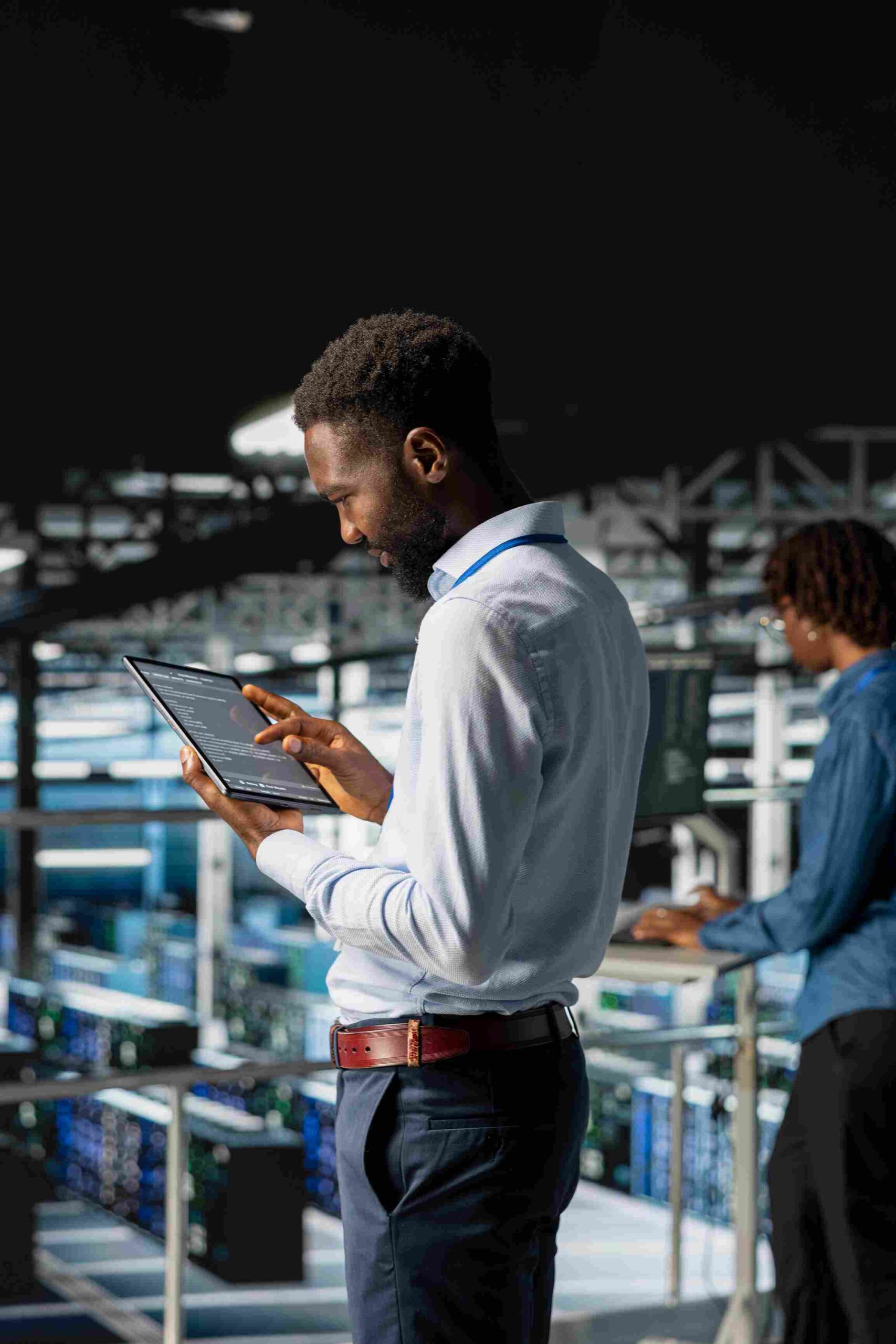

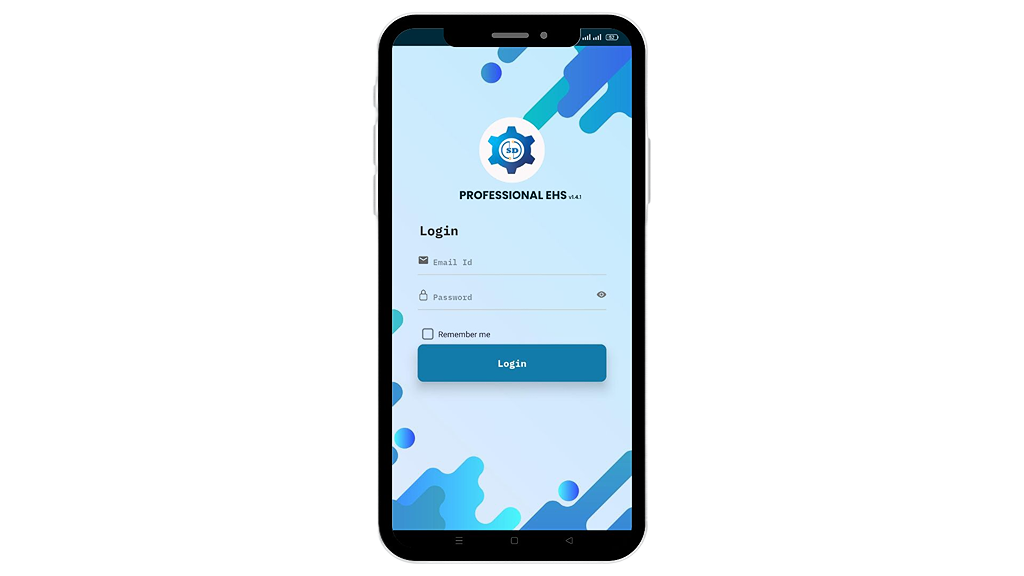

On-the-Go Inspections

Access inspection dashboards and reports from mobile devices, whether on the shop floor or offsite.

Flexible Integration

Easily integrate with existing manufacturing systems and scale with your business growth.

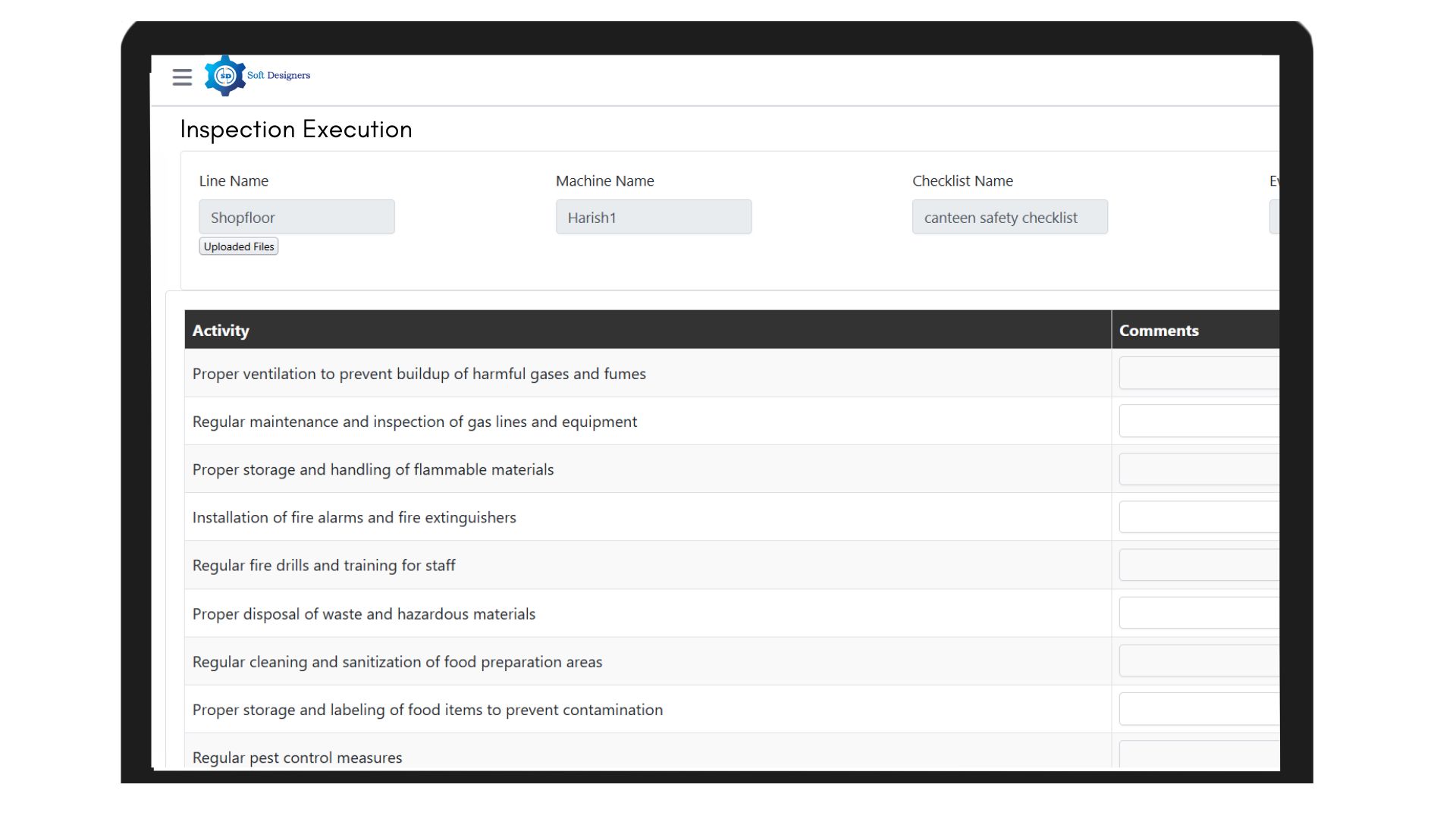

Compliance Assurance

Automatically generate inspection records to meet safety and regulatory standards with minimal effort.