Digital Incident Reporting and Tracking System: Empowering Safety Through Live-Time Insights:

In today’s industrial world safety people can’t wait for paper based forms. paper based forms are handwritten procedures, slow to investigate, and it takes a lot of time to get approval from each individual person.

That’s the main reason organizations are shifting the Modern Digital Transformation of Incident Reporting Systems to reduce the incident and Easy to Track the Incident reports ,Investigate the CAPA Actions Easy to handle in a digital way . These Digital system people allow for workers ,supervisors and safety teams, plant manager, capture and the incident and Analyse the process of incident in live time ,and creating A safety Culture for better improvement for the industry.

The Challenge: Manual Reporting Creates Delays:

Many Organizations Are still Stuck in the permit to work of Paper forms ,Excel sheet, Format for collecting the information from the Incident cases, and Near Miss Reports. This Not only saving Consumptions of time and also might be missing some information also possible.

By the same time A reports send the safety team and some incident details are missing means Investigation will take longer to check the Corrective Actions and get delayed approval under paperwork.

The organization wants a faster and accurate way to capture the correct safety data like where incidents exactly happen and when did it happen and that’s exactly what a digital incident reporting system helps with safety people.

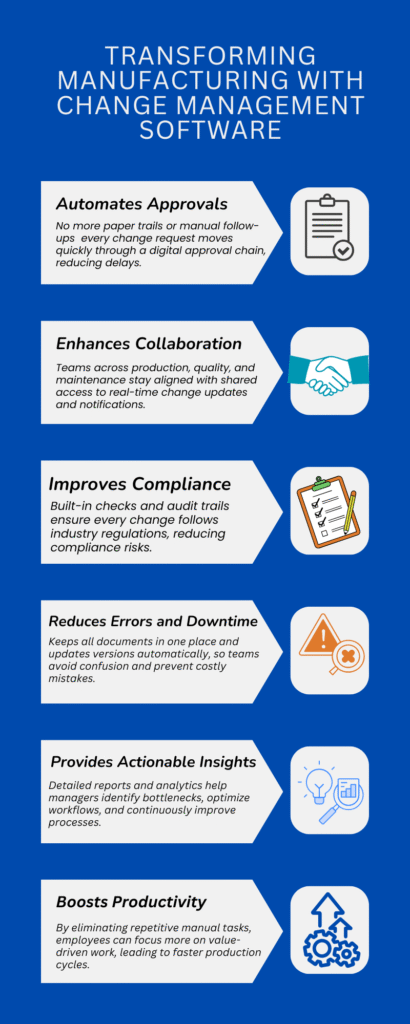

The Transformation: From Manual to Fully Digital Automation

A Digital incident Reporting And tracking systems transforming how the safety Teams manage to respond to incidents.

Using a mobile, workers can instantly record incidents, take pictures of photos, or videos and mention the location and submit the reports it automatically receives of Notifications of Supervisors. They will take immediate action to solve the problems. So Digital is Easy to Help the process go smoothly and properly .

How It Works

- Instant Capture: Employees report incidents, Near misses, or hazards in live time using mobile devices and websites.

- Categorization: The system classifies incidents by type, severity, and location for better tracking.

- Digital Approval Workflow: Supervisors and EHS officers review, approve, and assign corrective actions digitally.

- Live Dashboard: Safety leaders can monitor open, pending, and closed Approval of incidents with a visual dashboard.

- Safety Insights: View Live-time updates that help you understand what’s working and what needs attention.

Key Features of a Digital Incident Reporting and Tracking System

A digital incident reporting system makes it easy to record, track, and manage workplace incidents in Live time. It helps employees capture details instantly through mobile or web platforms, ensuring no information is lost. Interactive dashboards give safety teams a clear view of performance, trends, and risk areas for continuous improvement.

Mobile & Cloud Access: Report and review incidents anytime, anywhere even in remote or offline environments.

Photo & File Attachments: Capture visual evidence to improve the accuracy and clarity of reports.

Instant Notifications: Automated alerts keep all safety people informed on status changes and pending actions.

Custom Workflows: Set up approval steps and escalation levels that match your company’s safety structure.

Root Cause Analysis Tools: Integrated forms and templates like 5-Why or Fishbone help streamline investigations.

Data Visualization Dashboards: Instantly view safety metrics, KPIs, and performance trends.

Streamline Root Cause Analysis and Corrective Actions

Nowadays AI Technology is on Trend to Transforming How safety teams find out the causes and implement Corrective measures. Instead of spending lot of hours to analyse the reports in manual format, Digital system now helping the safety teams to reduce time ,Giving solutions for faster and more Accurately

- why – why Analysis of AI automatically creates a root-cause analysis from incident reports, improving consistency and reducing the valuable time.

- AI Suggesting quickly creates corrective action plans using incident details, enabling EHS teams to review and approve them in just a few seconds.

- Incident Communication: AI quickly summarizes the main details, findings, and lessons learned into short reports that can be shared right away with employees.

- AI Advisor: Finds incidents that could cause serious harm by comparing them with real examples from past data.

This AI-driven workflow ensures quicker incident closure, smarter decision-making, and continuous organizational learning all with minimal manual effort.

OSHA & ISO Compliance: Strengthening Your Safety Standards:

A digital incident reporting system helps organizations comply with OSHA standards such as:

- OSHA 29 CFR 1904 – Recording and reporting of workplace incidents

- OSHA 1910 – General Industry Safety Requirements

- OSHA Investigative Guidelines – Ensuring thorough documentation

Digital systems simplify compliance by:

✔ Maintaining complete incident records

✔ Providing timestamps, audit trails, and corrective action logs

✔ Ensuring timely reporting of severe incidents (within OSHA-required deadlines)

✔ Helping employers full fill OSHA’s hazard identification and prevention requirements

ISO 45001 Compliance (Occupational Health & Safety Management System)

A digital incident management platform aligns perfectly with the requirements of ISO 45001:2018, including:

- Clause 5.4: Worker participation in incident reporting

- Clause 6.1: Hazard identification and risk assessment

- Clause 8.1: Operational controls

- Clause 10.2: Incident investigation and continual improvement

Digital systems ensure ISO compliance by:

✔ Enabling structured reporting and investigation forms

✔ Supporting corrective and preventive action tracking (CAPA)

✔ Providing dashboards for safety performance metrics

✔ Ensuring continuous improvement through real-time insights

Use Cases for Each Solution:

| Practical Case | Feature | Outcome Delivered | AI-Powered Tools |

| Instant reporting from mobile ,or desktop | Incident Reporting | Captures incidents instantly with photos, videos, to ensure awareness ,with responsible | AI, Image Speed Detection, Auto-Tagging |

| Investigation& corrective action tracking | Investigation Manager | Simplifies investigations with guided workflows and automatic CAPA tracking for faster resolution | Root Cause AI, 5-Why Analysis, Alerts, and Action Track |

| Recording near-misses and unsafe Act | Safety observation | Identifying risks before they occur into incidents | Image of incident report AI, Behaviour Insights, and Risk Prediction Engine |

| Regulatory compliance and performance | Safety Visual Dashboard | Turns raw data into actionable insights with KPIs, charts, and compliance status | AI Analytics, Live-Time Dashboards, and Automated Reporting |

| Emergency alerts | Real-Time Alerting | Sends quick safety alerts to workers | AI Hazard Alerts |

Proven Results:

Companies adopting digital incident reporting systems have seen measurable improvements:

- 70% faster incident reporting and closure times.

- Increased employee engagement in hazard identification and near-miss reporting.

- Managers can easily monitor safety trends and team performance anytime.

The Future of Incident Management:

Final Conclusion of the Digital Incident reporting And tracking system are not just tools it is saving a lot of people’s life and giving Good safety Culture Environment. When every employee can report instantly, every manager can act quickly, and every manager can see clearly safety becomes smarter, faster.