Introduction: Preventing Accidents Before They Happen

In the manufacturing industry, where risky tasks happen every day, keeping the workplace safe is very important. Incident and near miss reporting software helps reduce risks by finding hazards early before they cause serious injuries or stop production. This software collects and tracks safety data in real-time, so companies can fix problems quickly, follow safety rules better, and build a stronger safety culture. Using this kind of software not only helps prevent accidents but also improves how smoothly the whole operation runs.

Why Incident and Near-Miss Reporting Matters

Near-misses are often early warnings of potential accidents. When reported and analyzed properly, they help:

- Prevent future incidents

- Uncover hidden hazards

- Strengthen compliance with EHS regulations

- Improve accountability across departments

Failing to act on near-miss data leads to repeat safety issues, rising costs, and increased regulatory scrutiny.

Common Near-Miss Incidents by Department in Manufacturing Workplaces:

- Production Department :

- Someone almost slipped or tripped near a machine because of spilled oil or other materials.

- Loose clothing or safety gear almost got caught in moving parts of a machine.

- An operator almost started the wrong machine because the labels were not clear.

2. Maintenance Department:

- Working on a machine without using proper lockout/tagout safety steps.

- A tool falls from a height but luckily doesn’t hit the person below.

- Risk of electric shock while checking a live electrical panel without wearing safety gear

3. Warehouse & Logistics:

- A forklift almost hit a person because the driver couldn’t see them due to blind spots.

- Stacked materials fell over, but luckily no one was hurt.

- A pallet jack rolled away and nearly hit a parked vehicle

4. Quality Control / Lab :

- A chemical spill that dries up before anyone comes into contact with it.

- A broken sample with sharp glass pieces close to hands or eyes.

- Using sharp tools in the wrong way while doing tests.

EHS Safety Department:

- A near miss was found during an inspection that had not been reported earlier.

- Someone entered a confined space without permission, but it was noticed quickly.

- A worker was seen on CCTV not wearing PPE in a hazardous area.

How EHS Software Helps Manage Near-Miss Incidents Effectively:

- Cost Savings through Prevention

- Tracking near-miss incidents helps spot dangers before they lead to accidents.

- Stopping just one serious accident can save a lot of money on medical bills, insurance claims, legal issues, and lost work time.

- Using data to analyze these incidents helps fix problems early, so you don’t have to keep spending money on the same issues.

- Real-Time Mobile Reporting

- Workers can quickly report near-miss incidents using a mobile app, including photos or videos as proof.

- The app is easy to use, so more workers are likely to report issues—especially from remote or dangerous areas.

- Instant Alert Notifications :

- Automated alerts are sent to safety teams, supervisors, or the right departments so they can quickly respond and fix the problem before it becomes serious.

- Analytics & Dashboard Insights

- Dashboards show patterns, danger areas, and repeated unsafe actions.

- The visuals help make better decisions and plan where to use resources.

- Easy CAPA (Corrective & Preventive Action)

- You can assign and track CAPAs directly in the system.

- The system also keeps an eye on follow-ups and deadlines, so there’s less chance of mistakes or forgetting tasks.

- Integrated Workflow Automation

- Near-miss reports help start important steps like investigations, checking risks, and reviews by managers.

- This saves time and helps the company follow safety rules like ISO 45001 or OSHA standards.

- Safety Culture Improvement

- Encourages employees to speak up and take action early.

- Creates a workplace where everyone stays alert and takes responsibility.

- Audit & Compliance

- All reports and actions are recorded with the date and time, making it easy to prepare for audits.

- It helps you easily meet regulatory rules and certification standards.

- Scheduling Safety Inspections

- Based on near-miss trends, inspections can be done more often in certain areas.

- This helps lower future risks by focusing audits where they’re needed most.

- Multi-Site & Cloud-Based Access

- A centralized system makes sure safety rules are the same at all locations.

- Cloud-based access lets you keep working even if there are system or network problems.

Using AI to Identify and Act on Near Misses in Manufacturing:

1. Real-Time Hazard Detection

AI cameras and sensors keep an eye on the production area all the time. They can quickly spot unsafe actions, like someone going into a restricted area, or notice if a machine isn’t working properly. This helps reduce the risk of accidents .

2. Automated Data Collection

AI systems gather information automatically from devices like sensors, machines, and wearables. This removes the need for manual reporting and makes sure that all near-miss incidents are recorded quickly and accurately.

3. Root Cause Analysis

Machine learning algorithms can find patterns in near miss incidents. AI helps discover hidden trends, like repeated problems with specific machines or during certain work shifts. It can also suggest possible root causes, making it easier to prevent similar incidents in the future.

4. Predictive Analytics

By analyzing historical data, AI predicts where and when near misses are most likely to occur. This allows proactive maintenance, retraining of employees, or changes in workflow to prevent actual accidents.

5. Incident Classification

AI can classify near misses by severity, likelihood, and impact. This helps prioritize response efforts, ensuring high-risk issues are addressed first.

6. Cost Reduction

By spotting problems early and preventing accidents, AI-based near miss management helps save money on equipment repairs, worker compensation, and lost production time.

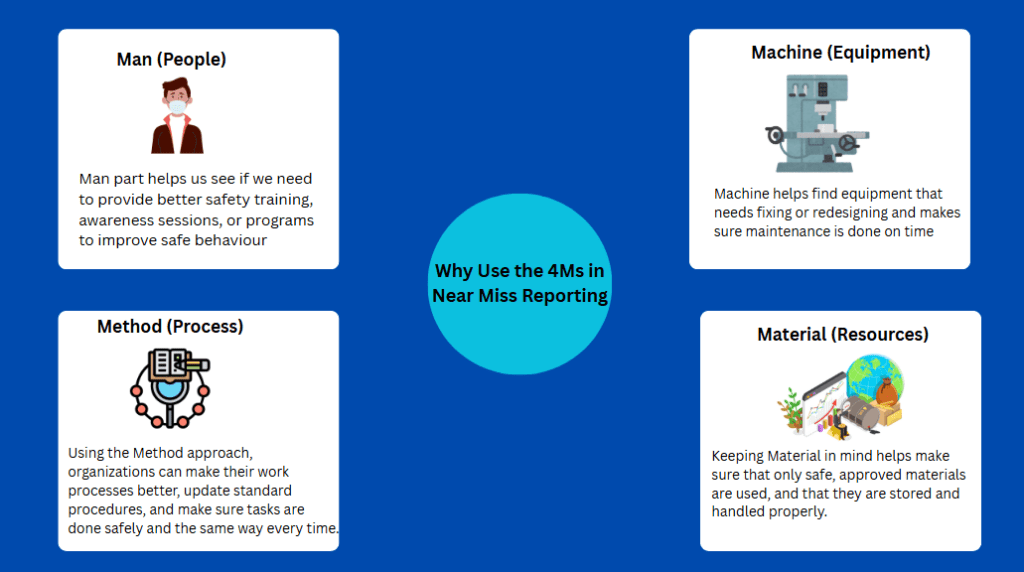

Why Use the 4Ms in Near Miss Reporting:

Action Tracking for Near Miss – Individual & Department-wise:

Tracking actions after a near-miss is very important in any workplace. It helps make sure that every safety issue is taken seriously and proper steps are taken to fix and prevent it. By keeping track of actions at both the individual and department level, companies can make sure everyone is doing their part. This builds responsibility, keeps things clear, and improves overall safety. Here’s how tracking at both levels works.

Tracking Individual Responsibility in Near Miss Cases

This process makes sure that specific tasks are given to the right people and are followed up properly.

- Personal Responsibility: When a near miss happens, each task is clearly given to a specific person like a maintenance worker, safety officer, or machine operator.

- Set Deadlines: Every task has a due date, so it gets done on time.

- Reminders and Escalation: If someone doesn’t complete their task on time, they get a reminder. If the delay continues, their manager is informed.

- Track Performance: This system helps track how seriously employees take safety tasks. It’s also useful for performance reviews and training needs.

Example:

If a worker reports a slippery floor, the housekeeping staff is assigned to clean it and put up a warning sign. A safety supervisor is responsible for checking that the job is done properly.

Department-wise Action Tracking

This helps us see what actions are being taken by different departments or teams.

- Finding Patterns: We can spot repeating problems in specific departments. For example, if the maintenance team often reports electrical issues, we know where to focus.

- Managing Workload: It shows if a department has too many open tasks. Then, we can shift some work to other teams to balance things out.

- Clear Responsibility: Department heads can check how their teams are doing in terms of safety—like how many actions are completed or still open.

- Improving Safety: Based on the near miss reports, teams can create safety programs or update their procedures.

Example:

If many near misses in the fabrication department are about not wearing PPE, the team will be asked to give PPE training and update their safety rules.

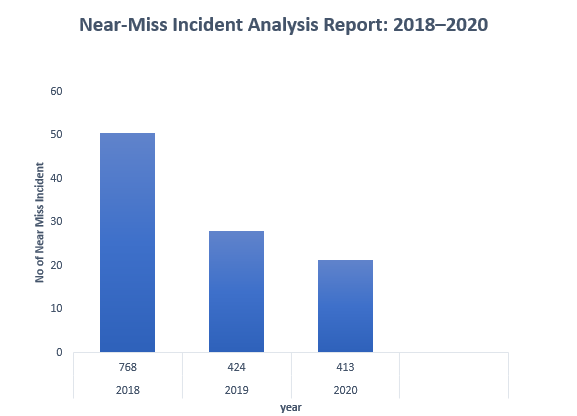

Historical trends of year wise Near Miss Incident Reports 2018-2020

Conclusion:

At Soft designers, we understand that in today’s fastmoving manufacturing world, taking action on safety isn’t just important it’s a responsibility. Incident and near-miss reporting software helps manufacturers find problems early, take quick action, and stop them from happening again. By using digital tools for reporting and investigation, companies can reduce risks, follow safety rules better, and keep improving over time. Choosing this kind of software is a smart step toward making your workplace safer, more efficient, and better prepared for the future.

Recent Posts:

NEAR MISS REPORTING: WHY IS IT IMPORTANT?

NEAR MISS REPORTING: WHY IS IT IMPORTANT?

The Importance of Near-Miss Reporting for Workplace Safety:

The Importance of Near-Miss Reporting for Workplace Safety:

Manufacturing Incident Reporting Software in Workplaces:

Manufacturing Incident Reporting Software in Workplaces:

Reporting Near Misses: Building a Strong Safety Culture

Reporting Near Misses: Building a Strong Safety Culture

Best EHS Software Solutions for Manufacturers in 2025

Best EHS Software Solutions for Manufacturers in 2025

The Importance of EHS Incident Reporting & Investigation

The Importance of EHS Incident Reporting & Investigation

The Definitive Guide to Incident Reporting Software

The Definitive Guide to Incident Reporting Software

A Comprehensive Guide to Safety Incident Reporting

A Comprehensive Guide to Safety Incident Reporting

Maximizing ROI with ESG Reporting Tool

Maximizing ROI with ESG Reporting Tool

The Impact of Delayed Incident Reporting

The Impact of Delayed Incident Reporting