Andon Systems in Manufacturing Industry

Visualize, Identify, Resolve: AR-Driven Andon Systems in Manufacturing:

Introduction:

In today’s fast-paced manufacturing environment, efficiency and productivity are paramount. To meet the demands of modern production, businesses are turning to innovative solutions such as Augmented Reality (AR) to optimize their operations. One area where AR is making significant strides is in Andon systems, which play a crucial role in identifying and resolving issues on the production line promptly.

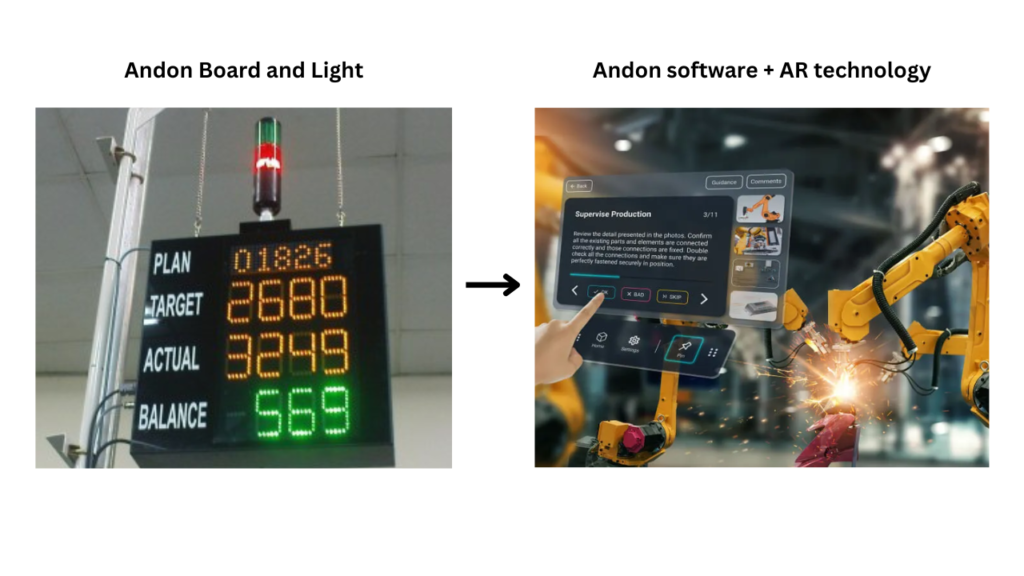

Traditionally, Andon systems have been a staple in manufacturing, providing a visual management tool to alert operators and supervisors of any problems that arise during production. These systems typically involve physical lights or displays that indicate the status of the production line, allowing teams to respond quickly to issues and minimize downtime.

However, with the advent of AR technology, Andon systems are undergoing a transformation. AR-enabled Andon software overlays digital information onto the physical environment, offering a more intuitive and immersive way to visualize and manage production processes.

Let’s explore deeper into how AR-driven Andon systems are revolutionizing manufacturing:

1. Visualization: AR technology allows operators to visualize key production metrics and information overlaid onto the physical workspace. Through Tab or mobile devices, workers can see real-time data such as cycle times, production targets, and quality metrics directly within their field of view. This enhanced visualization helps operators stay informed and make data-driven decisions on the shop floor.

2. Identification: One of the primary functions of Andon systems is to quickly identify and alert personnel to issues on the production line. AR-enhanced Andon systems take this a step further by providing contextual information about the problem at hand. For example, when a machine malfunctions, AR overlays may highlight the affected equipment, display error codes, or provide troubleshooting instructions, empowering operators to identify issues more effectively.

3. Resolution: Provided with actionable data from the AR-enabled Andon system, operators may speed up the resolution process. Whether it’s accessing maintenance manuals, contacting support staff, or engaging with colleagues remotely, AR technology makes problem-solving faster, reduces downtime, and improves production efficiency.

4. Continuous Improvement: In addition to immediate problem resolution, AR-enabled Andon systems contribute to a culture of continuous improvement. By capturing data on downtime, error rates, and maintenance activities, these systems provide valuable insights for process optimization and root cause analysis. Over time, manufacturers can leverage this data to identify recurring issues, implement corrective actions, and drive ongoing improvements in production efficiency and quality.

Conclusion:

AR-driven Andon systems offer an important change in production, providing operators with improved vision, faster problem identification, and more efficient resolution methods. By harnessing the power of AR technology, businesses can improve operational efficiency, reduce downtime, and stay competitive in today’s dynamic market landscape. As the manufacturing industry continues to embrace digital transformation, AR-enabled Andon systems will undoubtedly play a pivotal role in shaping the factory of the future.