Challenges and Opportunities For EHS Professionals

Revolutionary progression of the industrial sectors along the advancement of digital technologies Sustaining the Environment, Protection of workers Health and Safeguarding employees and work environment at the workplace is the challenging task of the EHS professionals to cope up with the updated technology and compliance of it.

EHS are the service providers to the industries. These services are fulfilled by the EHS professionals who are entailed with complex work through analyzing the problem associated within and improving the areas by protecting the workers who undertake the work.

EHS Professionals Faces Endless Challenges and These Challenges Serves as an Opportunities to boost the industrial sectors:

- Lack Of Access To Integrated Technology

Challenge:

The predominant challenge faced by EHS professionals are improper technology upgradation there are almost 50 to 60% of organization which are still using outdated technologies and manual processes to ensure environment health and safety of the workers and the workplace habitat. This practices not only damage environment but also exposes many risk in return less productivity with maximized expenses or loss.

Opportunity:

The digital shift of the EHS integrated with Artificial Intelligence provides cutting edge streamline operations along with real time monitoring and accessibility to the data whenever required which constantly manages the operation and benefits the EHS professional to manage health and safety seamlessly and mitigate the risk.

2. Analyzing The Risk and Mitigating The Risk

Challenges:

The major challenges faced by EHS professionals is to identify the potential risk and mitigate the risk before it becomes an accident. Collection of data is a prominent challenge for the proactive measure to prevent incidents.

Opportunities:

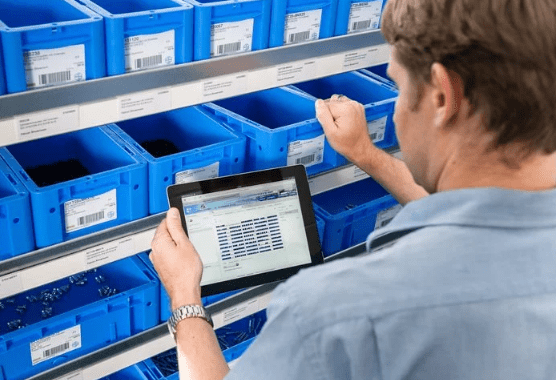

Leveraging the technology adaptation enables the ehs professional to collect data instantly and analyze the risk associated in real time with the risk assessment software system which provides proactive measures to mitigate the potential risk and enhances the safety and security of the work environment.

3. Employees Training and Engagement

Challenges:

Providing training and engaging employees to follow the safety and security values at the workplace is the crucial task for the ehs professionals to be dedicated and motivate the employees for the compliance of the safety culture to prevent illness, injuries or accidents at the workplace.

Opportunities:

Digital or online form of training system enables discussion of safety culture and best safety practices, combines different department employees and educates how to record and report the hazardous events whenever found in surroundings instantly as it is accessible through mobile phone or tablets. Thus the digital shift enables the ehs professionals to provide ongoing training and compliance of the safety culture through real time monitoring.

4. Compliance Of Safety Regulation

Challenges:

Training and education of safety culture doesn’t make no sense if the compliance of the safety regulation is not followed by the employees which might lead to increased accidents unsafe environment to work.The inspection of compliance of the safety regulation becomes a difficult task to ehs professional to detect the compliance of regulation all the time.

Opportunities:

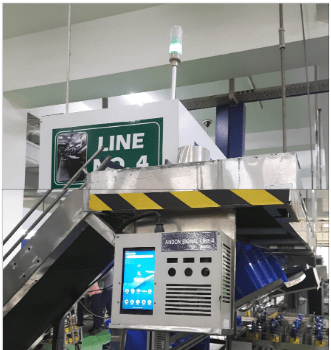

The integration of Artificial intelligence detective surveillance detects the compliance of the safety regulation instantly everywhere at the same time. It detects in real time and monitors with real time alerts and notification to the workers for the proper usage of Personal Protective Equipment to prevent risk and hence reduces the burden on ehs professionals of inspecting the compliance of safety regulation at the workplace

5. Effective Usage Of Resources

Challenges:

Effective utilization of resources by reducing wastage of resource and increasing productivity becomes very challenging work for the ehs professional to implement and sustain the resources which are limited or sometimes shortage that must be maintained much carefully.

Opportunities:

Leveraging the advanced technology of the EHS software system which enhances productivity creates the innovative management system which maximizes efficiency by saving cost. These benefits can be analyzed through the EHS software program called Return On Investment(ROI) which enables the professional to perform seamlessly.

CONCLUSION

EHS professionals face enlarged ongoing challenges to mitigate the risk and ensure environment health and safety of the organization to overcome the challenges the digital software solution enables them to perform their work smoothly and efficiently for the development of organization and positive image of the employer.