Smart factory industry Overview:

For a “traditional” industry to become a Smart Factory, it mostly requires the involvement and motivation of the company management to have a vision towards digitization, as well as professionally knowledgeable work teams dedication and coordination that can lead the transformation. However, all these statements for management and for a team of professionals must work with the technologies and tools that will help and allow them to control, analyze and improve production and plant times:

- Cloud monitoring, better known as the cloud, where you can store all the information and the large volume of data that is generated both in the plant (robots, sensors, intelligent devices …) and in the specific tools (MES, ERP…).

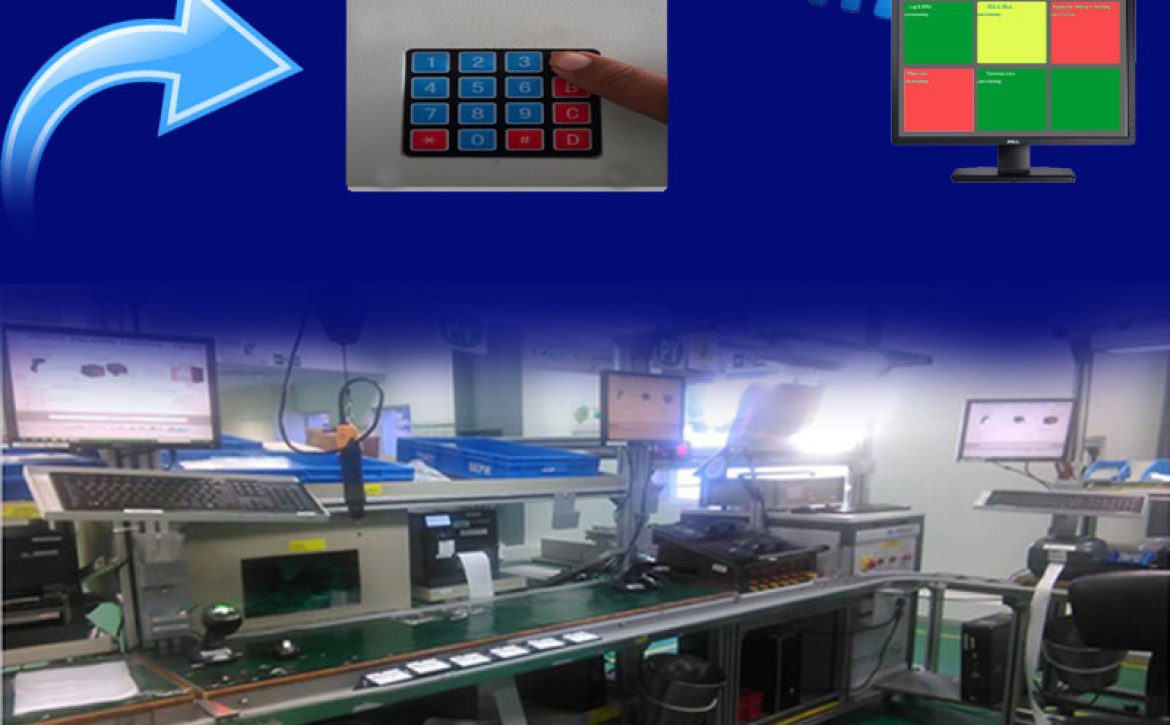

- “Internet of Things” or IOT. Connectivity between machines allows you to coordinate systems, capture the real time data, have remote control of production, as well as exchange information between systems and products.

- Data collection and analysis All information generated through connections between machines or plants and tools must be collected and analysed in real time with two objectives: the first is to identify patterns; and, the second, prevent future events. Gathering and analysing data is a crucial notion in the concept of the Factory 4.0, as it enables to unleash the potential hidden in the equipment, resources and people.

- Cybersecurity is an essential technology in a Smart Factory since privacy and data protection is the most key aspect for industries.

- Virtual and Augmented Reality help operators with product organisation, production tasks and equipment maintenance and repair. But we must not confuse both terms; when we speak about augmented reality, we refer to the technology that allows us to overlay, in real time, digital information to information that is perceived through our eyes requiring only a smartphone. While virtual reality requires special glasses to transport ourselves to the virtual world.

Click the below link to know more about Digital or Smart factory implementation