Understanding e- Preventive Maintenance

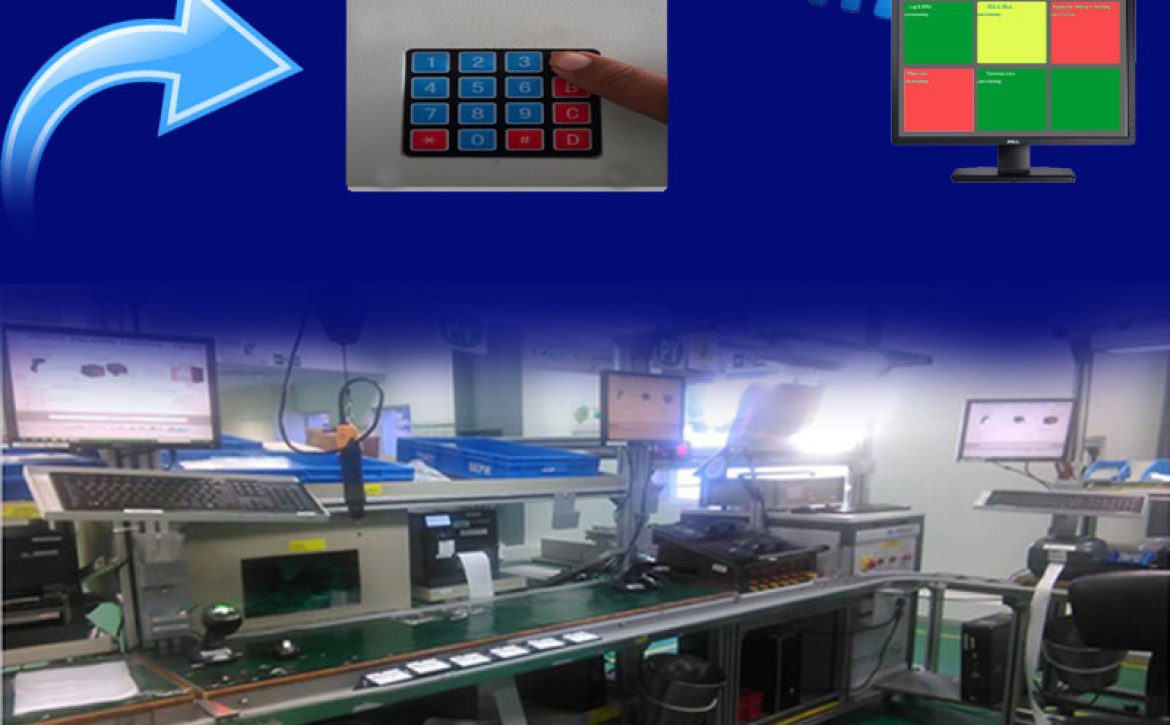

Preventive maintenance is an important part of the management of any type of infrastructure, contributing to the increase of equipment lifetime, the decrease of unplanned downtime, and, ultimately, the reduction of long-term maintenance costs

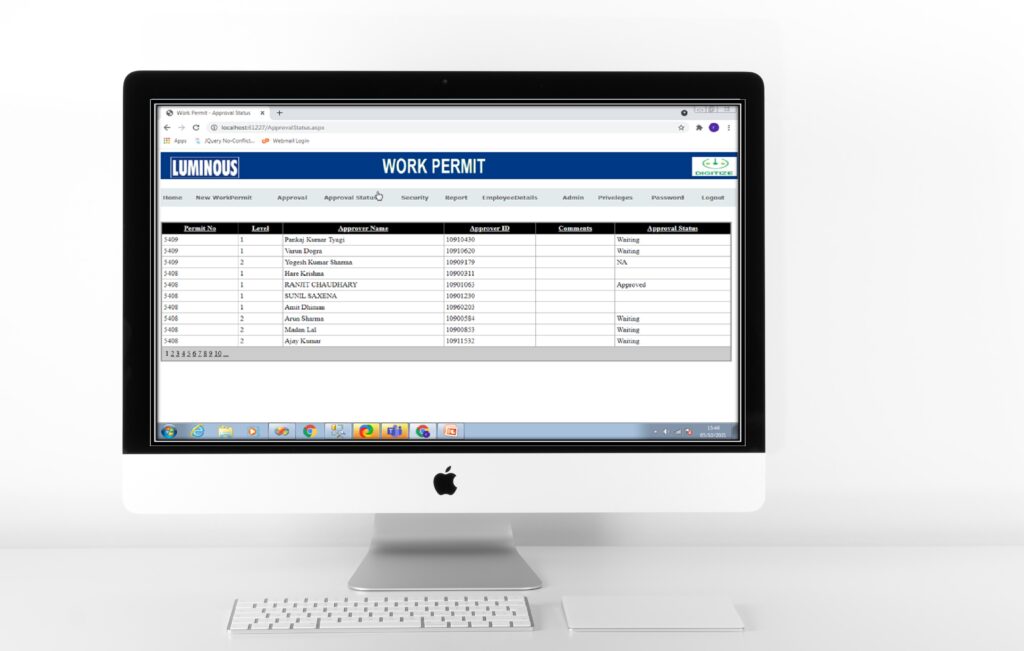

What is e- Preventive Maintenance

Preventive maintenance consists of interventions that prevent breakdowns and decrease the probability of an asset failing. That is, it is a type of planned maintenance that is performed even when a piece of equipment maintains its operational capacity.

It can be as simple as cleaning the filters on HVAC appliances or inspecting the bearings on centrifugal pumps, but it also includes more complex inspection plans, calibration and/or gauging plans, detection of gas leaks and other cyclic revisions.

Benefits

- Reducing downtime and increasing effectiveness (OEE)- E-PM avoids unscheduled downtime, which increases equipment uptime and availability, improving the overall efficiency of the equipment

- Increase in asset reliability- PM makes the equipment more reliable: they work properly for longer and have a greater lifetime

- Reduction of reactive maintenance costs – Preventive maintenance reduces the cost of parts and transport – just imagine the cost of ordering a part for the HVAC system overnight from an international supplier. It’s a known fact: emergency maintenance almost always involves very expensive repairs. In the worst-case scenario, a lack of maintenance requires the replacement of the asset

- Increased security- PM and regular overhauls detect wear on parts and keep equipment in optimal condition. This offers more safety to those in contact with the asset, both employees and customers

- Greater comfort – Whenever we talk about a building used by a large number of people, preventive maintenance also contributes to offering more comfort to its customers. Maintenance ensures that all equipment is in full operation, without having to shut down the entire system to make a repair

Learn more about Digital preventive maintenance